Carrara marble and the Apuan quarries

The Etruscans

The beginnings of the extraction of white Carrara marble date back to the 6th century BC, by Etruscan craftsmen active in Pisa and Volterra, witnessed by about a hundred various monuments (cippi of various shapes, decorated stone bases, large vases, but also female statues and large figured cippi found in the Pisan and Volterra area. The various petrographic analysis have established the Carrara origin of the Apuan marble used for these artifacts.

The Romans

The Romans used to extract already in the 2nd century BC Bardiglio marble in the eastern area of Carrara,

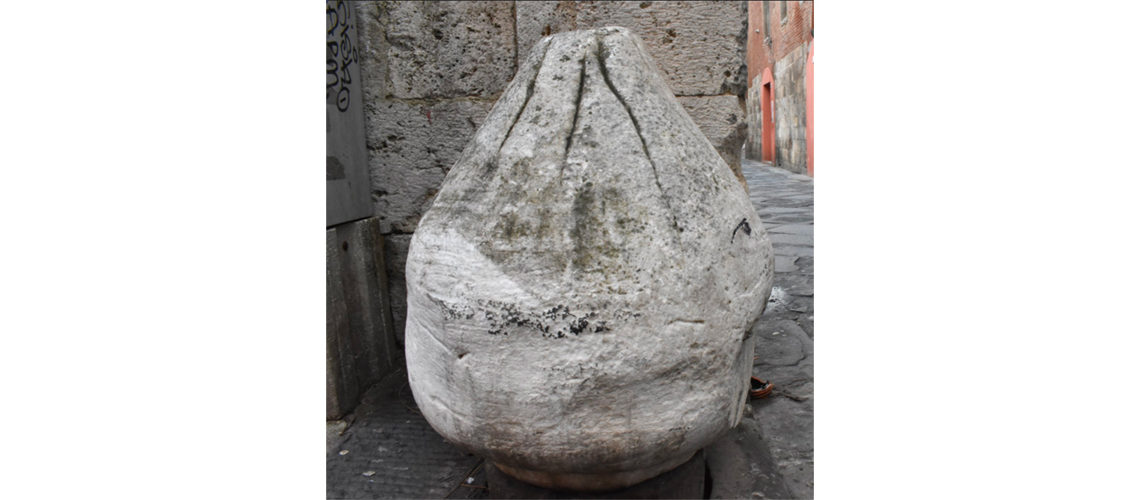

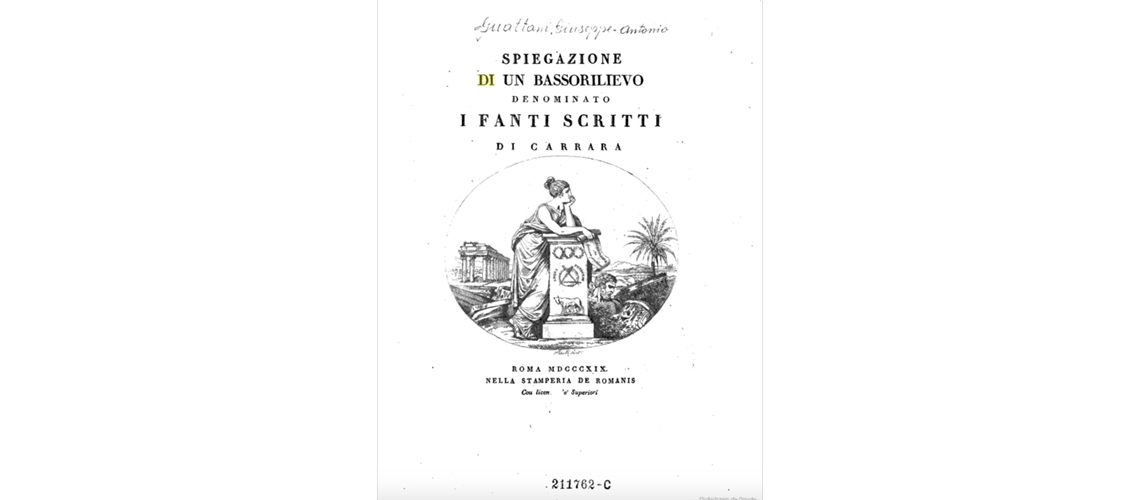

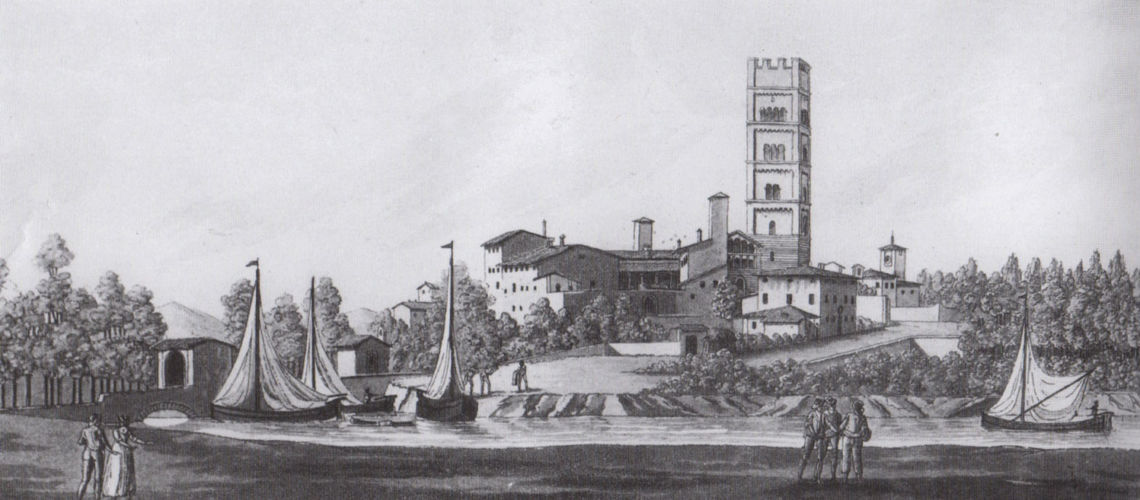

but they discovered in the Polvaccio area a marble quarry better than the Greek one, with a tight grain, very fine crystallization, very bright whiteness, semi-transparency: the Statuary. In the first century BC the Romans conquered the Apuan territory and increased the exploitation of the quarries. Under the emperor Tiberius the best quarries were bought or confiscated and entered the imperial heritage; in an area inside the current Carrara Roman remains indicate the presence of offices and homes of Roman officials who collected the vectigal, the tax placed by the emperor on marble, from which the toponym Vezzala still in use.The port of collection and marble sorting was Luni, about 10 km from the quarries. The excavation of marble, managed on an industrial scale, made this city the most important marble center of the Mediterranean, and its wealth lasted until the 3rd century AD The blocks were transported by large tonnage vessels. The main destination was Rome, but marble was also exported to Provence, Spain, and North Africa. Slaves, prisoners sentenced to forced labor and even free craftsmen worked in the quarries. 189 Roman quarries have been identified in which were found tools, square and marked blocks, coins, parts of sculptures and columns, and sacred aedicules. The most famous, dating from the beginning of the 3rd century AD is that of the Fantiscritti from which the quarries took their name, carved on the marble of the mountain, detached and kept at the Academy of Carrara. It depicts Jupiter embracing his sons Hercules and Bacchus (transformation of the indigenous divinity into Summit God also found in Luni). It was custom of the visitors of the quarries to engrave their signature on the Roman aedicula, as Michelangelo, Giambologna, Canova did and in Russian letters the Russian general Osterman Tolstoi.

Marble extraction

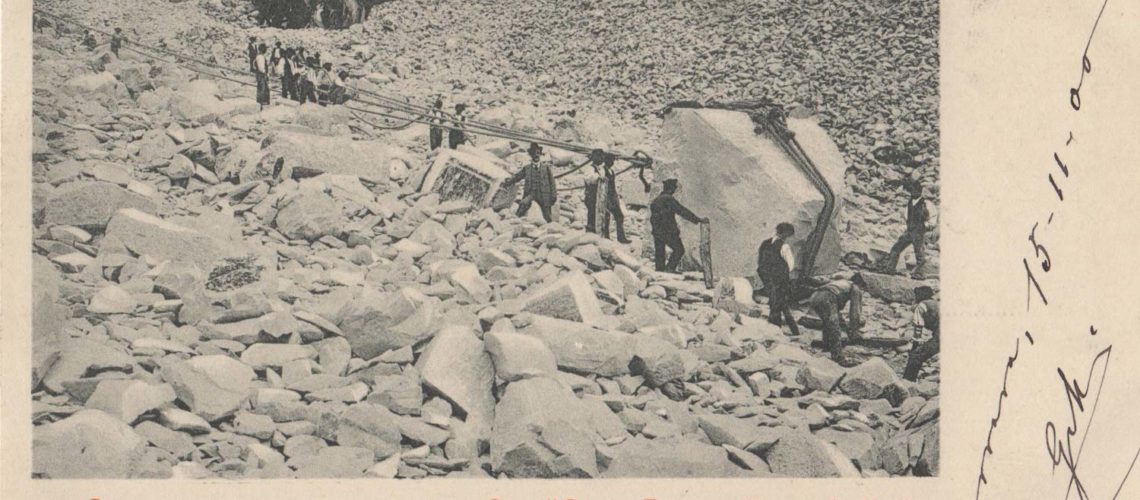

The extraction method was mainly based on identifying the natural cracks of the marble and on acting on them for the detachment of blocks: a “V” groove was performed on the block above the natural crack, in which wood wedges were hammered and they were wet; the expansion of the wood cracked and detached the block from the mountain.

In some cases it could be enough to detach the block hammering some iron pins into the natural crack of the marble.

Each marble worker belonged to one of the specialized categories: the marble-cuters who removed the marble blocks in the quarries, the squares that lined the blocks, the sectorial serrarii specialized in sawing the blocks, the lapidaries or the stonemasons, the marble polishers were the pulitores, then the sculptores, then the characterarii sculptors of letters and inscriptions of the gravestones. The blocks were transported downstream to the place reachable by the carts, using the lizza: it was a matter of letting the blocks slide by gravity slowly in a controlled manner on the sides of the mountains on some species of wooden sledges held upstream with ropes.The way of the ancient Romans of detaching blocks from the mountain was used until the nineteenth century, when dynamite started to be used.

Late antiquity

With the art and architecture of the early Middle Ages, the reuse of marble from Roman ruins was born, especially columns and capitals for churches, and sarcophagi for the remains of important people and major saints.

The Middle Ages and the Renaissance

It is after 1000 that the extraction of marble starts again in the Apuan quarries: for the construction of the Cathedral of Pisa completed in 1092, of its Baptistery of 1163, of the bell tower of 1174, and of the monumental Camposanto of 1214.

In 1265 Nicola Pisano went to the Carrara quarries to choose the marble for the pulpit of the Cathedral of Siena, in 1302 Giovanni Pisano did the same for the pulpit of the Cathedral of Pisa, and in 1319 large quantities of marble were purchased for the church of Santa Reparata of Florence. In the 1400s, under the lordship of the Malaspinas, the marble worker’s corporation took power, where the number of quarry workers increased year by year, and during the Renaissance the greatest artists arrived in Carrara to choose and buy marbles.

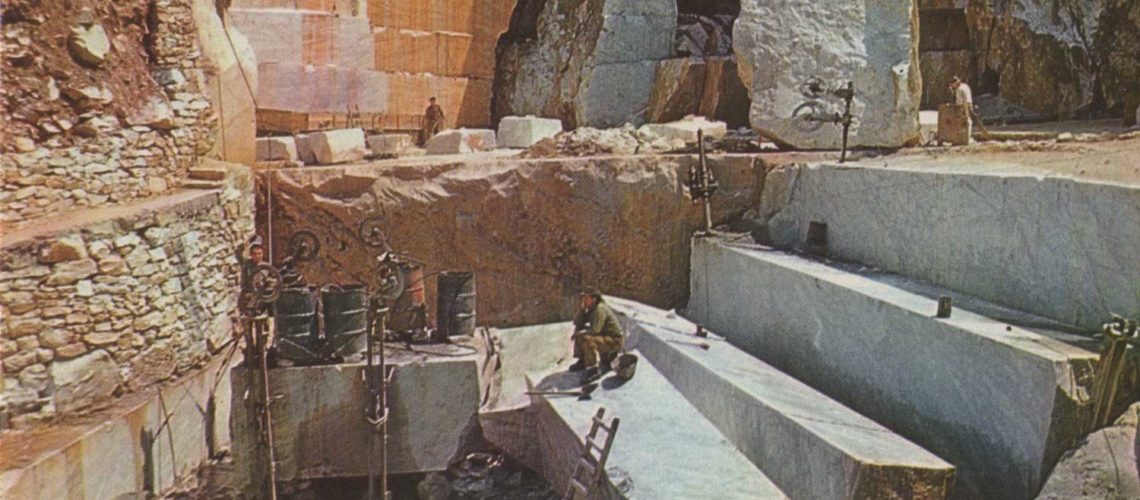

In the quarry

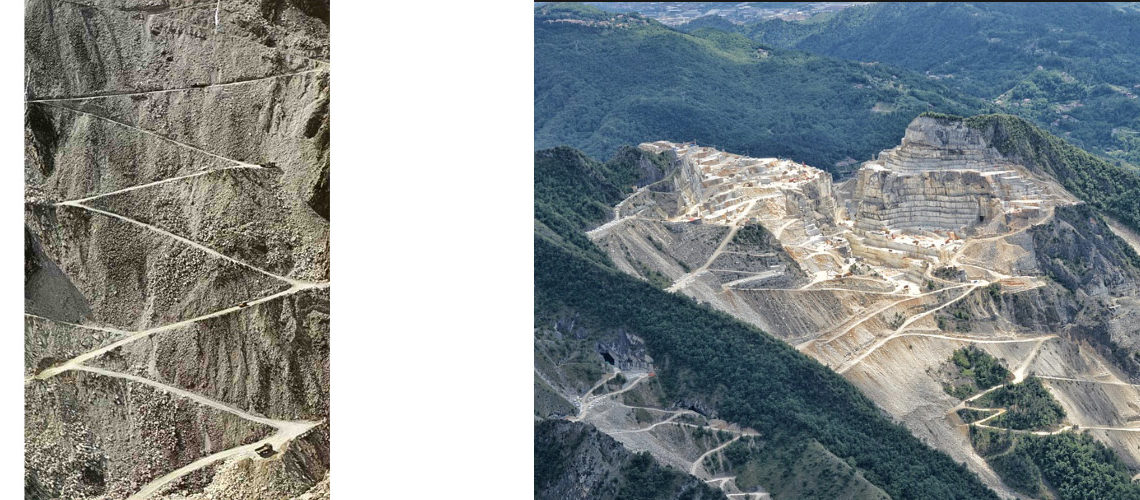

As we have seen the mining technique in the quarries, and also the way of transporting the blocks to the port of Carrara, have remained the same since Roman times until the 1800s. The creation of fairly safe roads that can be traversed by wagons in the quarry areas have always been a difficult and dangerous undertaking.

The attempt was therefore to bring the blocks from the quarry to an underlying flat area, called the poggio caricatore, to which it was possible to access with a driveway. The operation was the lizza, the one already seen for the Romans, that is the lizza, and it happened in the same way. We continue to use the weight of the load to be lowered to obtain the braking action; the lizza (the sled) on which the blocks were loaded, or more blocks, was made to slide on a floor of wooden sleepers called parati; if necessary they soaped it to reduce friction. When it went over the wall, they moved the parati in front of the lizza, putting new soap, and so on until the arrival. The lizza was connected with large ropes to wooden poles driven into the rock, called piri,

around which 3 or 4 turns of cables were wound, so that the friction slowed the descent of the load.

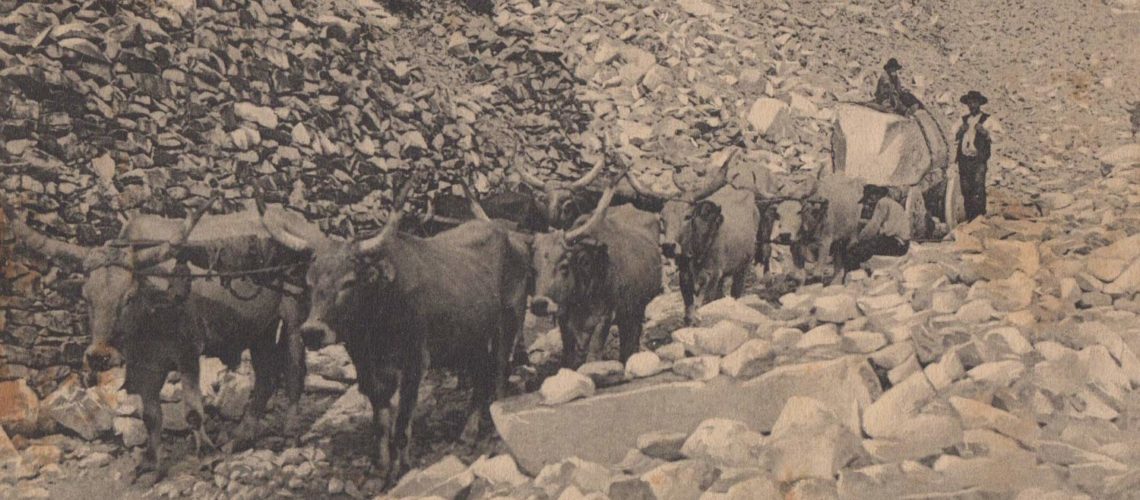

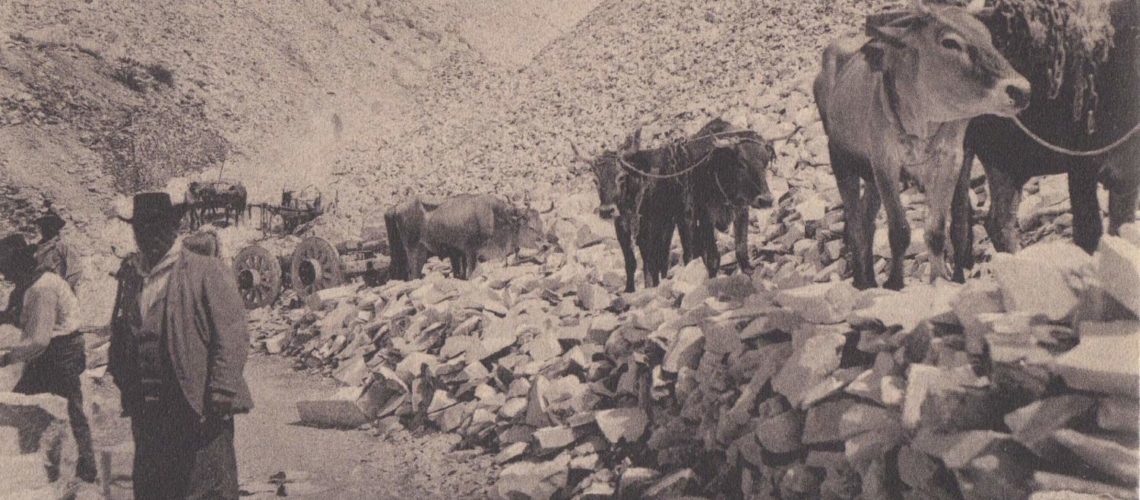

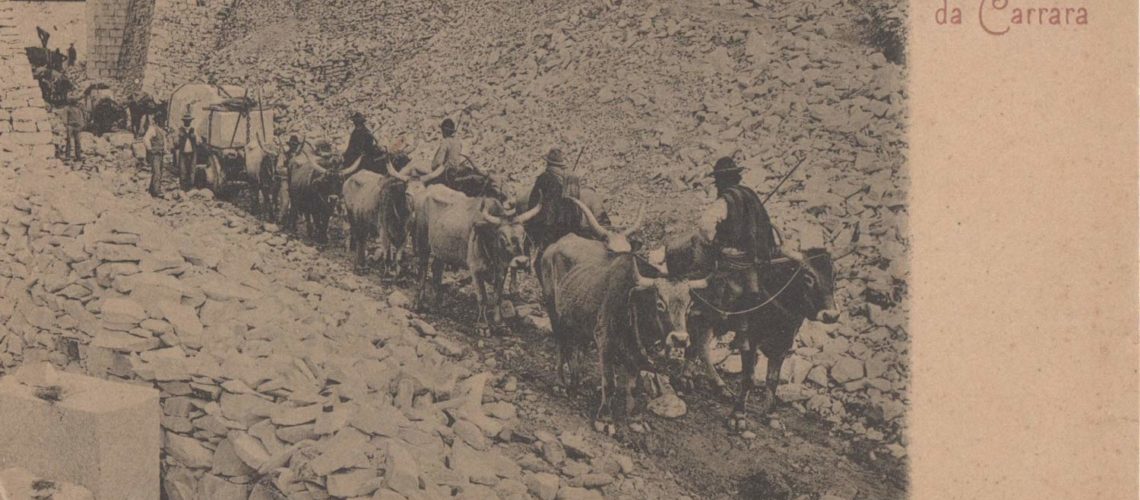

At the poggio caricatore, the blocks were loaded on very low carts with large, sturdy wheels to support the weight of the marble, pulled by oxen.

The couples of oxen increase according to the size and weight of the blocks.

The charts traveled about 10 kilometers separating Carrara from the port, where the marbles were transferred to the ships to transport them to various ports.

For Florence the ships transported the blocks to the port on the Arno of Pisa, on smallest ships called navicelli

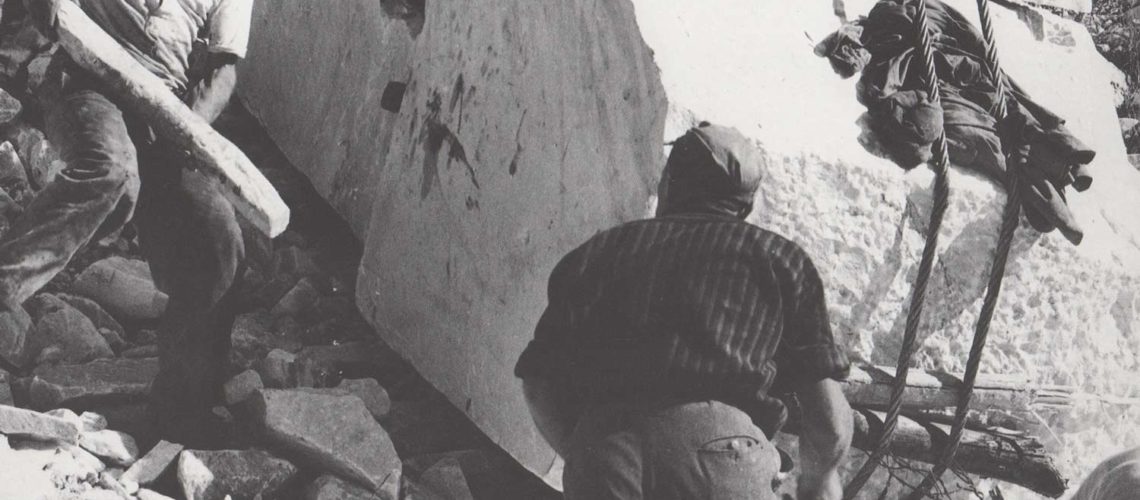

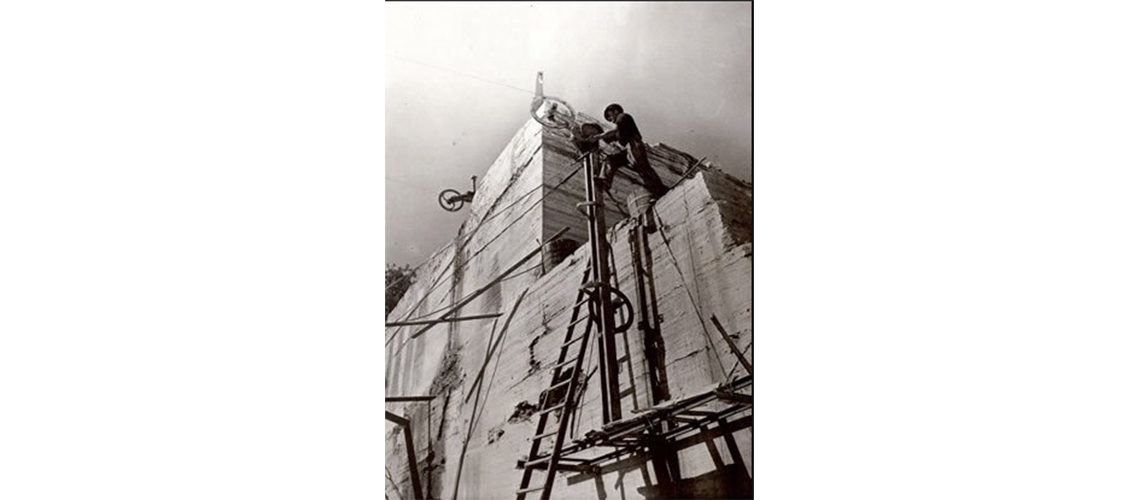

that went up the river to the port of Signa, where they continued until they reached the city through carts pulled by oxes. A particular fairly dangerous job was carried out in the quarry by the tecchiaioli, workers who suspended themselves along the walls of the quarries to eliminate with iron spikes, any areas of the blocks in which friability could be recognized, to avoid falling marble fragments on the quarry work surface.

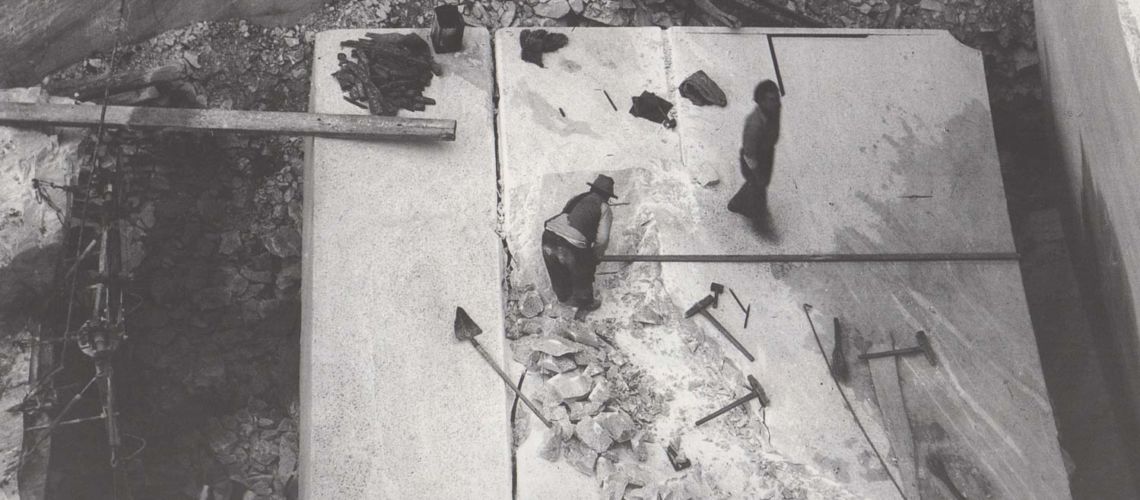

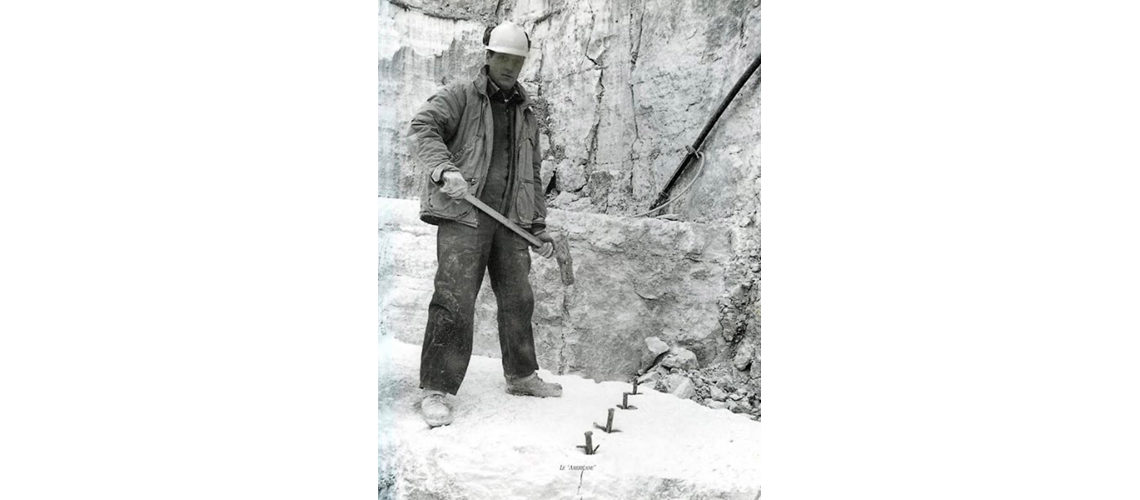

In the ‘800 for the extraction of the marbles from the quarries was started to be used the gunpowder a practice that continued up to the first years of the ‘900. The use of mines allowed the detachment of very large parts of marble from the mountain. The mine blasting, known as varate, were not frequent, because after each collapse of the quarry wall the blocks had to be worked, cut to size and squared. The marble wall was pierced by drilling deep holes into which the explosive charge (the mine) connected to the detonator was inserted. The hole was closed and the chard was blew up. First, however, a particular tuba was played for a long time, emitting very low notes, to warn of danger.

In this way less than 50% of the marble detached from the mountain was employable, and the waste was therefore very high. Over time, the quarrymen learned to use less powerful and more controllable explosive techniques that produced less waste materials. A further novelty occurred at the end of the 1800s with the invention of helical wire cutting. It is a thin rope with a diameter of about half a centimeter, made of three twisted steel wires. With mobile pulleys, positioned and blocked on the step of the quarry bank from where the block is to be removed, the cable is passed and continuously run by pouring over it silica sand and water which, transported by the cable, kept under pressure over the block, abrade the marble slowly cutting it. The circuit is a few hundred meters long, and this allows the wire to cool down by getting rid of the heat produced by friction with the marble; a motor pulley gives the wire movement about 5 meters per second.

The ability to manufacture diamond wire has made much faster the cutting of blocks from the mountain: on the wire with a diameter of 5 mm there are small bulges (called perline) close together, each of which is covered with diamond dust blocked: it is made to slide on the marble like the helical wire, but the cut is much faster.

The cutting area is cooled with a continuous jet of water. Even the transport of the marble blocks has completely changed since the post-war period: has been started to use military American trucks left in Italy, and this encouraged the creation of roads that reach the quarrying plans, without the need to carry out the picturesque but slow and dangerous way to get the blocks down into accessible areas. Until a few years ago, the trucks were loaded with winches of the trucks.

Today the load on modern six-wheel drive trucks takes place thanks to the enormous excavator blades of which the quarries are always equipped.