The art of lost wax casting

Part 2

The negative moulds made on the sculptures to be cast in bronze are used to obtain a positive wax of the sculpture itself, of the same thickness that the bronze should have.

The wax thus obtained is retouched, i.e. any imperfections are removed,

until it is perfect and ready to be incorporated into a three-dimensional network of castings,

and then covered with a refractory material called “loto”.

The “loto” mould containing the wax is cooked in the furnace for several days

Cooking melts and burns the wax contained in the “loto” moulds, leaving the empty cavity with the shape of the burnt wax inside.

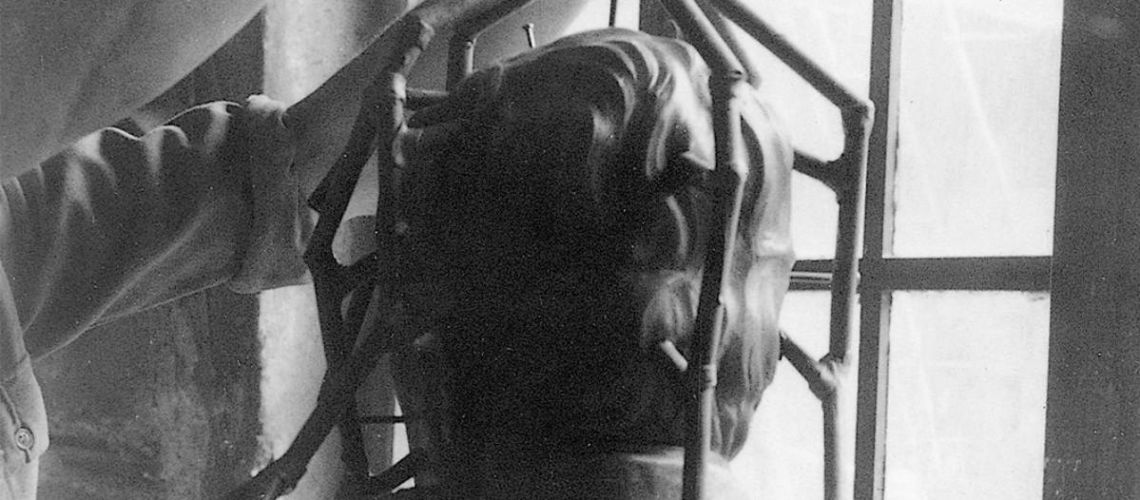

After cooking, the “loto” moulds are placed in a hole in the ground.

We now proceed to the melting of bronze alloy,

And to the casting of the molten bronze into the “loto” moulds;

Bronze thus takes the place of wax; the moulds are broken to extract the bronze castings

The castings are freed from the castings and sandblasted to clean them from the “loto” leftovers.

The castings are now cleaned and chiseled,

e successivamente rimontate a freddo e poi saldate.

The last phase is the patination of the sculpture: it involves oxidizing the surface of the bronze in the same way that the atmosphere would, over the years, but much more quickly

The lost wax casting technique has remained the same for centuries. Today, of course, methane is used instead of coal for the melting furnaces and for the furnaces for cooking “loto” moulds, electric tools such as hoists, cranes, forklifts, etc. that allow the handling of heavy parts, once done completely by hand.

The only changes related to the materials were the replacement of organic gelatin to make the negative moulds with silicone rubber, and the replacement of beeswax, now very expensive, with paraffin.

Even bronze welding is no longer oxyacetylene flame but takes place with electric welders in an argon atmosphere.