Fountain of the Tritons in Malta - Part II

The restoration

The priority has been given to the elimination of the reinforced concrete poured inside the fountain when it was placed at the end of the 1950s on the travertine base.

The Maltese technicians thought in this way to “strength” the brass sculptures and to find a clever way for blocking them on the base.

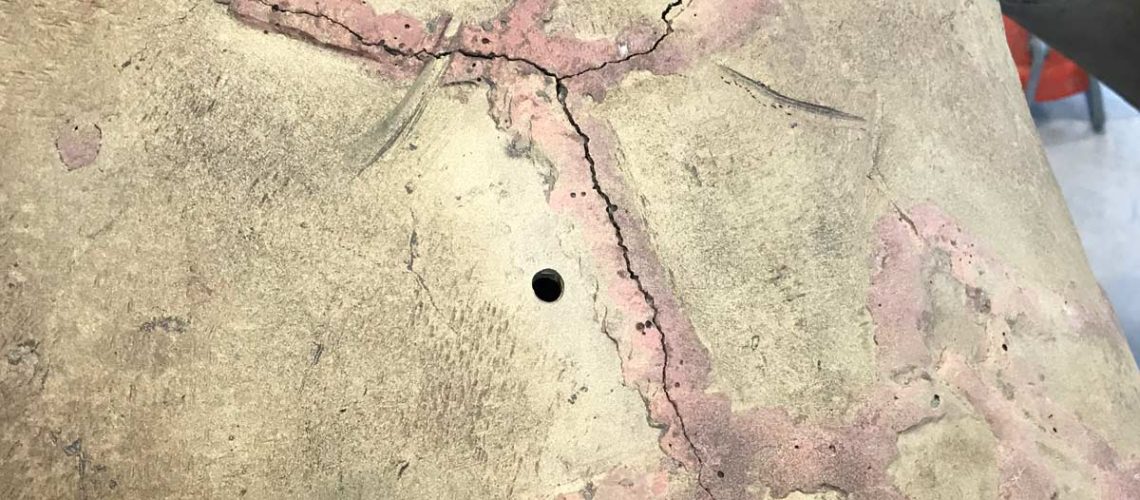

Instead the internal cement has helped to “cook” the metal and to create a dense network of cracks.

After the collapse of the fountain in the 70’s due to improper use of the overhanging brass basin, summary repairs were carried out to restore the fountain itself as best they could.

On this occasion the folds, indentations and other damages at the external surface, due to the trauma, were filled with epoxy material. The second restoration work was to eliminate these fillings to see the real state of the sculptures.

The expansion of the cement and its emission of chemical liquids has made the brass alloy very fragile, crushing it at various points. Furthermore, the lost-wax casting technique was badly respected by creating areas very thin.

The work continued with the cleaning of the surfaces through micro sandblasting, also allowing the elimination of the outbreaks of oxidation and sulphation and of the calcareous infiltrations due to the cement and the water of the fountain.

The Neapolitan foundry left on the sculptures the totality of the “spacing nails” necessary for the lost wax casting, some in iron and others in copper. Their chemical reaction (oxidation and sulphation) caused damage to the surface of the sculptures.

It was necessary to eliminate these nails and widen the holes left by their extraction to completely eliminate the chemical reaction outbreaks.

From here began the work of consolidation of the many parts deteriorated, weakened, broken in several pieces, and of the many cracks born in the sculptures, through external and internal weldings of the sculptures, complex and delicate work caused by the bad state of the metal.

A particularly difficult and delicate job was that of restoring the original shape to the basin, shape that it had lost both due to the breaking and folding suffered in the collapse of 1978, and to the bad repairs it had subsequently. A series of steel templates have been built with different degrees of curvature that have been used to recreate the exact original curvature of the basin. This has been cut in many points, brought back into shape and re-welded.

It’ been important to recreate the perfect coplanarity of the entire basin to allow, once reassembled on the fountain, the right and equal fall from the edges of the water.

Visits by the Maltese authorities ended with friendly lunches.

When all the parts have been consolidated and reinforced, the reassembly of the sculptures begun.

An internal stainless steel skeleton was inserted inside the tritons to unload the weight on the base of the fountain, so as not to burden on the sculptures. The skeleton was designed so as to allow the passage of the fountain’s water and electric lighting cables inside it.

and a stainless steel radial frame has been designed and built to consolidate and not burden on the brass basin with the weight of the water.

Only at this point it’s been possible to reconstruct the original position and wiring of the tritons and the basin, and to prepare a series of steel templates necessary to reassemble the entire fountain in Malta.

We proceeded giving patina to the sculptures,

then with the packing,

then with the transport to Malta.

The technicians of the Marinelli Foundry applied the stainless steel brackets for the reassembly of the fountain on its original concrete base, assembly carried out thanks to the 3D virtual models prepared previously.